Small Fiber Metal Laser Cutting Machine For Pipe

| Type | TKF-T-1500W/2000W/3000W |

| Laser power | 1500W/2000W/3000W |

| Laser medium | MAX. RAYCUS ,IPG etc. |

| Laser wavelength | 1070nm |

| Min. line | ≤0.15mm |

| Max. Range speed | 30~50m/min |

| Max. Travel of Y axis | 500~1000mm |

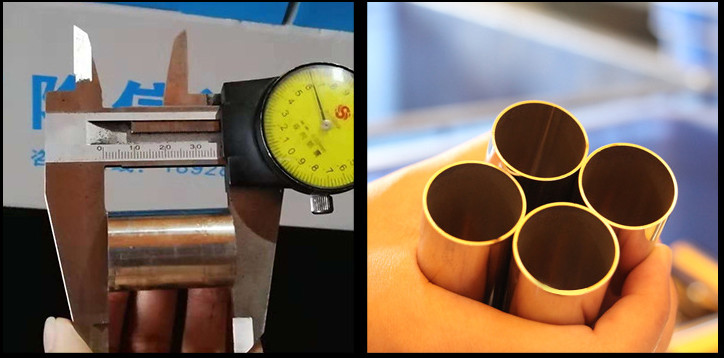

| Max. Round tube cutting area | ф50~ф100mm |

| Axial positioning accuracy of the bench | ≤±0.03㎜/m |

| bench repeated positioning accuracy | ≤±0.03㎜/m |

| 304 stainless steel thickness cutting range | 0.5--4mm |

| Power supply requirements | 380V/50HZ |

| Total power supply protection level | IP54 |

| Machine installed capacity | 18KVA |

| Num. | Main configuration | contents | manufacturer |

| 1 | Laser | ●fiber laser | MAX. RAYCUS ,IPG etc. |

| 2 | Industrial control machine | ● CPU I5 ● Graphic function ● storage 8G ● Computer communication interface, Ethernet, USB interface, etc ● solid disk 256G ● WINDOWS 10 operating system ● LCD |

customized by Techkey Laser |

| 3 | Pneumatic system composition | ● electromagnetic valve | Japan SMC |

| 4 | Transmission system composition | ● High-precision straight-line guide rail | Taiwan HIWIN |

| ● servo motor and driver | Japan Panosonic | ||

| 5 | Cutting head and capacitive vertical tracking system composition | ● fiber cutting head | Swiss brand |

| ● capacitive transducer● amplifier(inset)● adjustable box | Shanghai friendess | ||

| 6 | Electrical system composition | ● contactor | Schneider of France |

| ● photoelectric switch | Omron in Japan | ||

| ● terminal | Germany weidmuller | ||

| ● Tank chain | Cangzhou, Hebei | ||

| 7 | Software | ●CypCut LaserCut | Shanghai,friendess |

| 8 | Cooling system | ●professional cooler | KSTAR |

| 9 | Specialized cutting pipe cabinet | Customized by Techkey Laser | |

| 10 | Specialized cutting pipe fixture | Customized by Techkey Laser |

1 With Brand cutting head, high precision cutting

The internal structure of the laser head is completely sealed, which can prevent the optical part from being polluted by dust.

2 Small blind area for tailings, saving materials

The simple feeding method enables the machine to normally cut tails ≤100mm, which is far lower than the market value of tails of 220-300mm, saving domestic material loss and eliminating the tailings processing process.

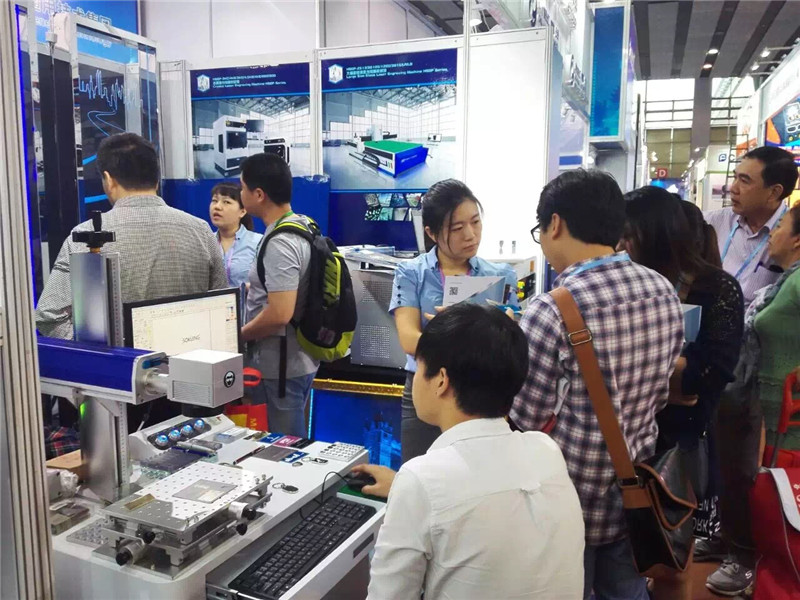

3D laser machine area

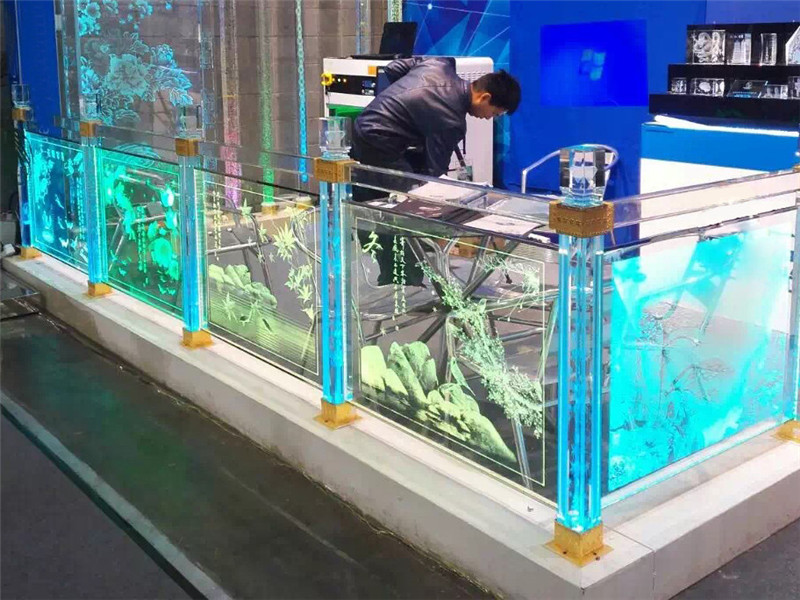

L size glass subsurface engraver

Pipe Cutting Machine

Cutting Machine

Factory Buidling

Products categories

-

Phone

-

E-mail

-

Whatsapp

whatsapp

-

WeChat

-

Top